Contact Us

Telephone:86-754-88101756

E-mail:hjktop@hjktech.com

Address: Block A, North of Haihe Road, Wanji Industrial Zone, longhu district, Shantou City, Guangdong Province

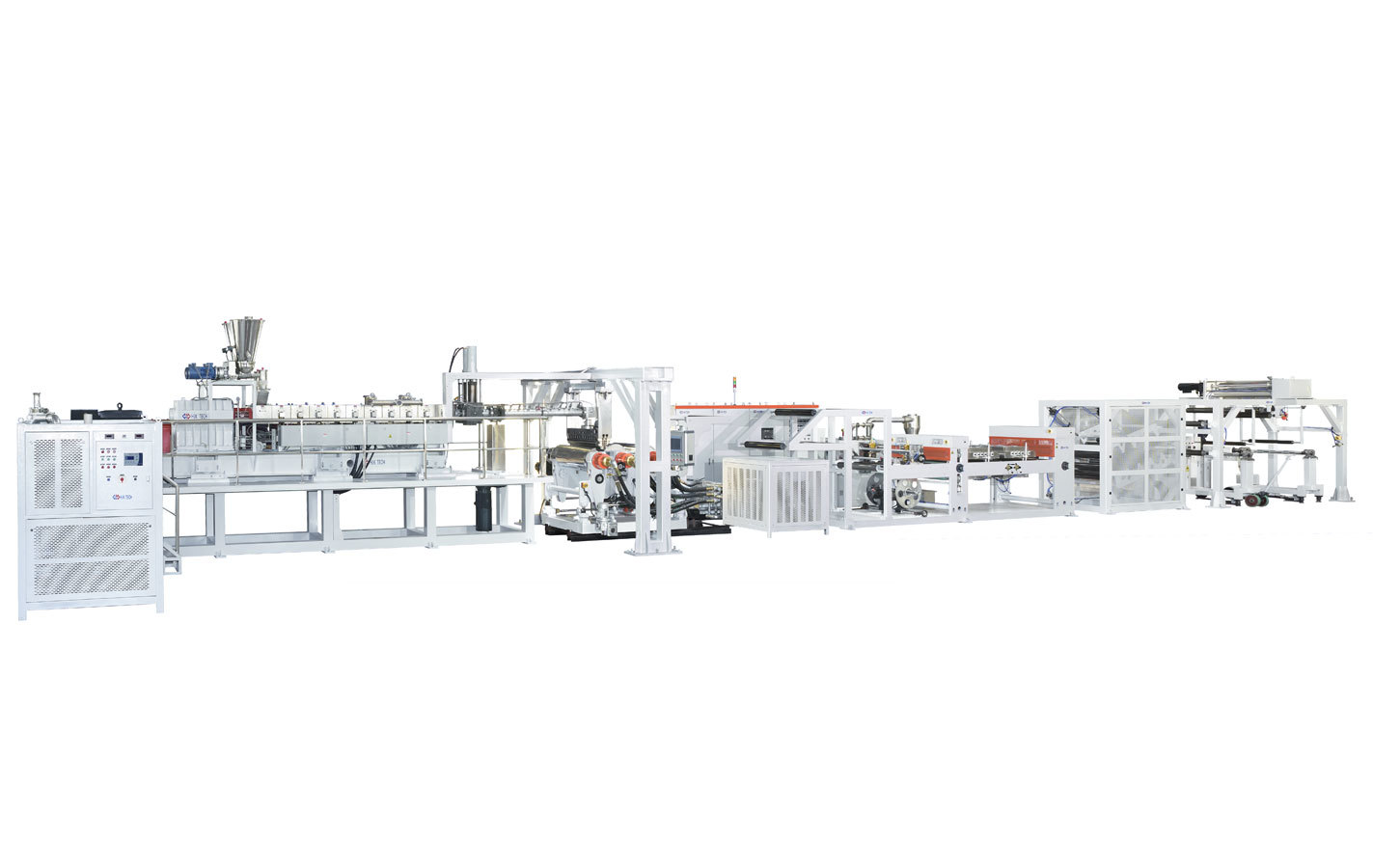

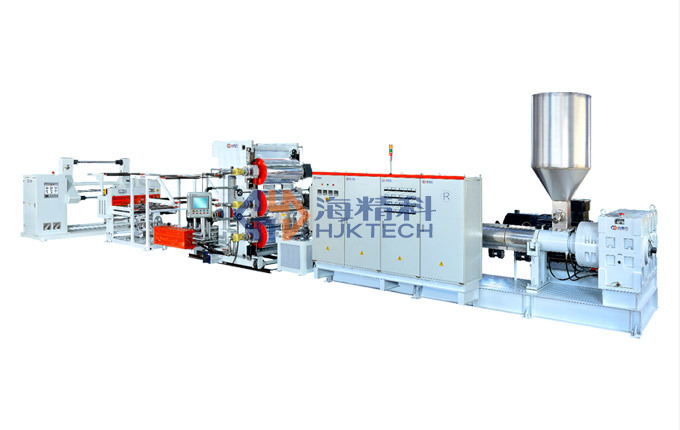

Large output PP, PS plastic extrusion sheet unit

Summary: The production line adopts a new extrusion system-co-directional parallel batching and mixing twin-screw extruder, which has the characteristics of starvation feeding, high-efficiency mixing, devolatilization and exhaust, self-cleaning performance, building block combination and stable extrusion. It fully applies its special performance, is connected with auxiliary film forming machines, and has the advantages of integrating mixing and forming, thus saving space, reducing labor and saving energy. In processing PET/PLA sheets, through the special optimization design of the vacuum exhaust system, it is not necessary to configure the raw material drying system. On this basis, if the crystallization device is added, the sheet products will be more competitive.

Key words: twin-screw, sheet machine

- Product Description

-

Equipment parameters

Model Mixing drum quantity Sheet thickness (mm) Effective width of sheet (mm) Maximum extrusion capacity (kg/h) HUP105-900 3 0.3~2.0 ≤ 700 300 HLJP120-1000 4 ≤ 820 400 HUJP150-1000 5 ≤ 820 600 HUP150-1400 5 ≤ 1280 600 Note: specifications can be customized according to user needs

Product Introduction

In order to meet the needs of large-scale and efficient production, effectively reduce labor and save energy, our company has developed a large-output PP and PS plastic extrusion production line by digesting and absorbing international advanced technology and combining its own optimization and innovation characteristics, which fully solves the confusion of batch production of single products and insufficient supply of production capacity, and replaces multi-machine, small-output and high-energy-consuming equipment.

Finished Products Application

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

Product inquiry