How to operate the casting machine correctly

Release time:

2022-04-20

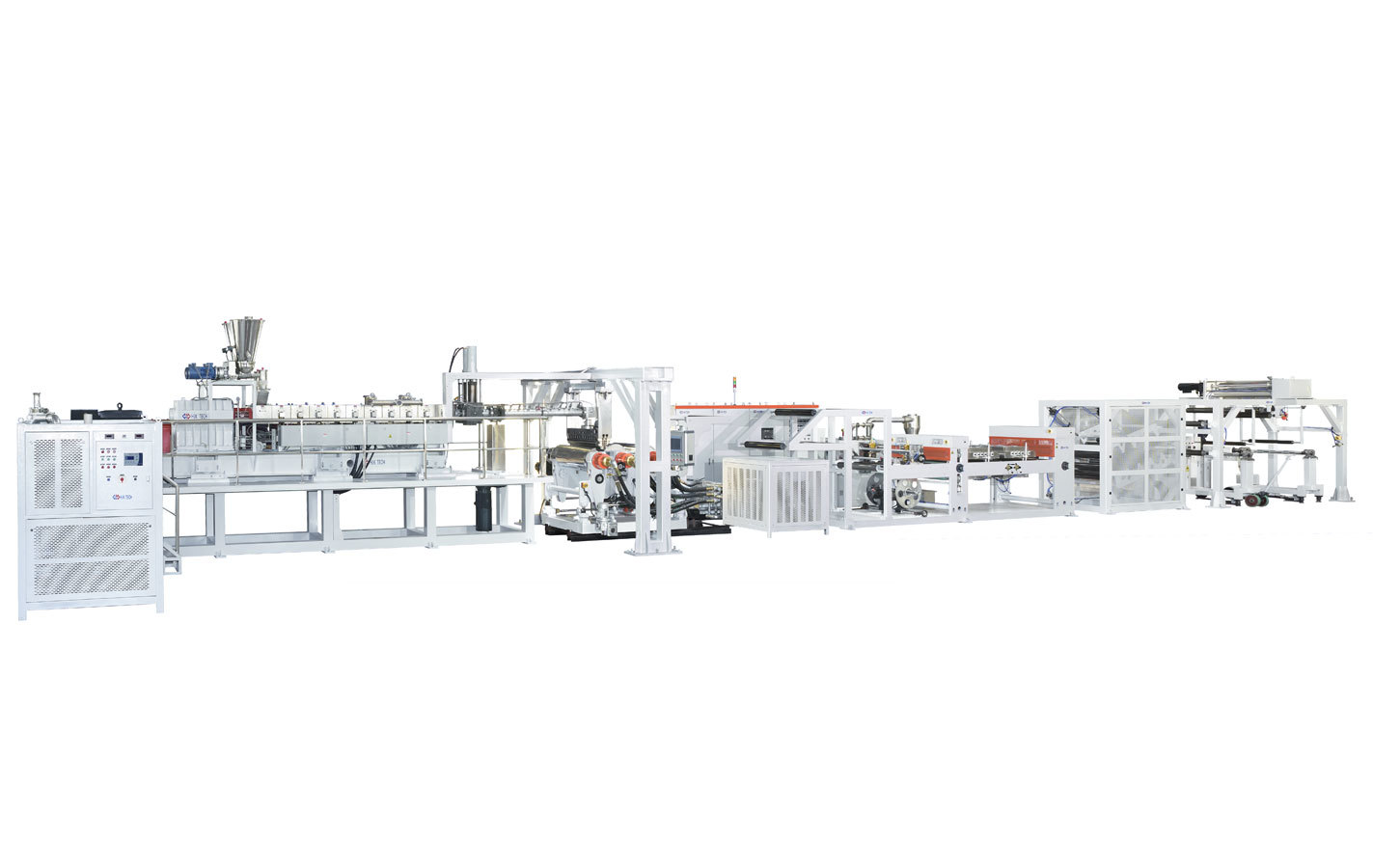

For most users who have bought a casting machine, its structure and characteristics must be familiar to everyone. On the basis of a certain understanding of the casting machine equipment, the correct use of the casting machine equipment can bring great help to the entire production process.

For most boughtcasting machineFor many users, its structure and characteristics are certainly familiar to everyone. On the basis of a certain understanding of the casting machine equipment, the correct use of the casting machine equipment can bring great help to the entire production process.

After buying a casting machine, the first thing to do is to understand the product specifications in detail. Most casting machine equipment will have some special and professional operating terms and procedures, which are usually rarely or even invisible in our daily life. Therefore, a careful understanding of product specifications is of great help in this regard. Understanding the basic functions and control operation of the casting machine is the basis of using the casting machine.

Secondly, pay attention to some details during use. Suchcasting machineThe surrounding water stains, because the water can conduct electricity, and the casting machine itself is a live product, so it is necessary to prevent the occurrence of leakage accidents. Secondly, in order to ensure the normal operation of mechanical equipment, daily maintenance is also essential.

In the modern production environment, a variety of large-scale industrial machinery is essential, large-scale casting machine is one of them. For such a huge equipment, if there is no correct operation method, not only the production will become inconvenient, but it will even bring some safety hazards to the operators. Proper operation of large casting machines.

1. Check whether the rotation and pressure of each roller of the casting machine are normal, and whether the heat exchange system, pump and pressure gauge can work normally.

2. Pass through each roll with a film through, then turn off the chill roll and press the film.

3. Start the casting machine, check whether the thick sheet and the melt have been bonded flat, and then tighten the thick sheet to the personnel at the exit.

4. Adjust the appropriate working position and complete all operations carefully.

5. After the end of production, manually willcasting machineAdjust to the non-working position, then introduce the material into the receiving tray and stop the casting machine.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

Previous Page

recommend News

Share