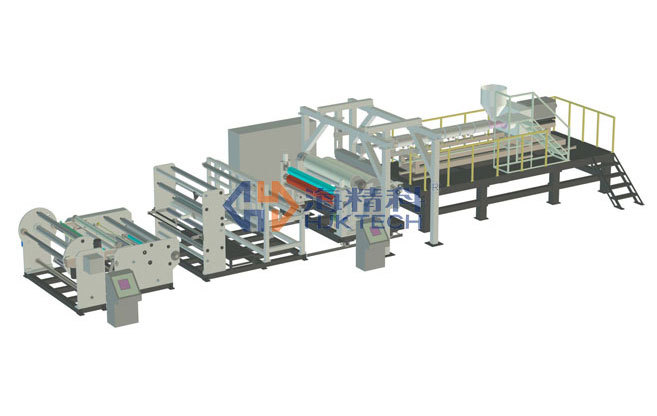

Large and medium-sized casting machine product application details

Release time:

2023-02-06

After buying a large and medium-sized casting machine, the first thing you need to do is to have a comprehensive understanding of the product instructions. Most mechanical equipment products have some special and professional practical terms and procedures, but these are generally rare or even invisible in daily life. Therefore, careful mastery of the product instructions is of great assistance to the application of large and medium-sized casting machine products.

Everyone is buying large and medium-sizedcasting machineIn the future, what needs to be done first is to have a comprehensive understanding of the product instructions. Most mechanical equipment products will have some special and professional practical terms and procedures, but these are generally rare or even invisible in daily life. Therefore, careful mastery of the product instructions is of great assistance to the application of large and medium-sized casting machine products.

medium and largecasting machineProduct application details:

1. Adjust the moderate working position and strive to complete all practical operations;

2. Cross each roller with the film thickness, then turn off the cold roller and lightly press the plastic film;

3. Prepare metal sheet and other relevant special tools, ethanol, stripping agent, etc. in advance;

4. After the production and manufacturing, manually adjust the casting machine to the non-operating position, and then introduce the raw materials into the Murata capacitor to terminate the casting machine;

5. Run the casting machine to check whether the sheet and solution have been neatly bonded, and then tighten the sheet to the staff at the entrance and exit;

6. Check the rotation status of each roller of the casting machine, whether there is any problem with the working pressure of the heat exchange system, and whether the pump and barometer can operate normally;

7. Check whether the material pipe, each roller and the surrounding area of the casting machine are clean and tidy, then use ethanol, paraffin and sand cloth to clean the mold, or use metal sheet to clean, and then spray the stripping agent;

8. After the production and manufacturing, the casting machine is manually adjusted to the non-operating position, and then the raw materials are led into the receiving plate to terminate the casting machine.

In the process of use, attention should be paid to some details, such as the water trace around the large and medium-sized casting machine, because the water can be conductive, and the casting machine itself is a power-on product, so it is necessary to avoid the power accident. In order to ensure the normal operation of mechanical equipment products, daily maintenance is also very important in daily life.

Applicationcasting machineIs your method right? How to apply the casting machine correctly? Here we often pay attention to the correct usage, because the actual operation of incorrect casting machine application will also reduce the safety factor of the casting machine, and will affect the service life of the casting machine. Naturally, some netizens ask which casting machine is better and how to choose the casting machine manufacturer. Many people are actually concerned about the technical service and after-sales service of the casting machine.

For most consumers who have purchased a casting machine, the structure and advantages of the casting machine must be very familiar to everyone. Only by understanding the system and grasping its proper use can it bring some assistance to all production processes.

1, buy casting machine, product instructions must read!

After purchasing a casting machine, all you can do before installing the application is to look at the product instructions first.

Most industrial equipment will have some specialized and professional practical terms and processes, which are generally almost invisible or even invisible in our daily life. Therefore, carefully grasping the instructions for use of the product is of great help to this matter. The understanding of equipment and basic elements is the basic use of the casting machine.

2, the application of casting machine to ensure safe actual operation and small details to solve

When applying the film casting machine, it is necessary to pay attention to some detailed problems: for example, the water trace around the casting machine, because the water can be transmitted, and the casting machine is originally a power-on product, so it is necessary to avoid the occurrence of power-off events.

3, casting machine maintenance is essential at ordinary times

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

recommend News

Share