What is the difference between a casting machine and a blown film machine?

Release time:

2023-02-13

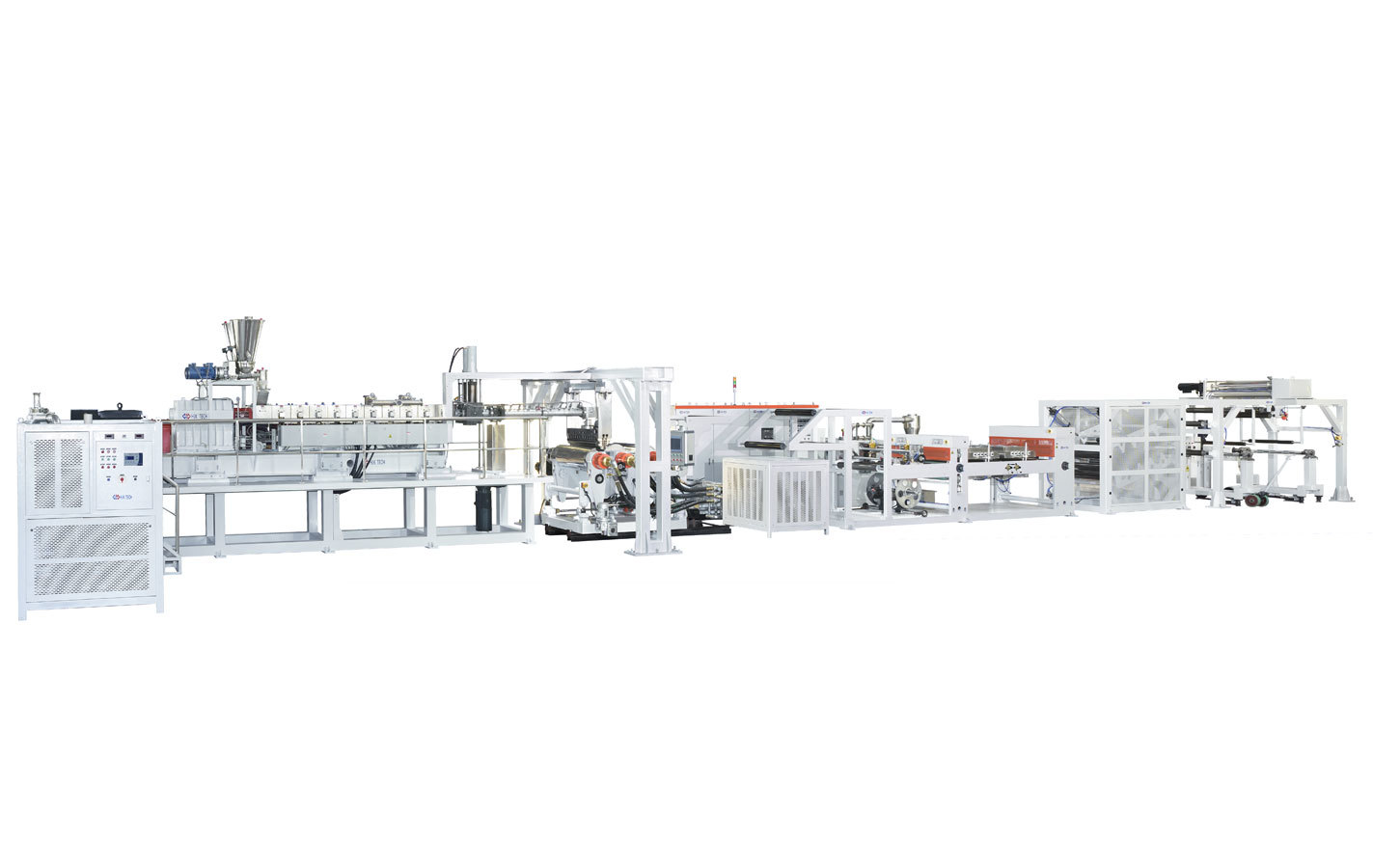

The casting machine is a professional equipment for casting film. It is mainly formed by mixing the crushed particles with adhesive, tackifier, thickener and organic solvent to make slurry with a certain viscosity. The slurry flows down from the silo and is scraped and coated on a special baseband chip with a certain thickness scraper. It is mixed and formed by drying, tackifier, thickener and organic solvent, then, according to the size and appearance of the finished product, the green embryo belt shall be subjected to production and processing such as shearing, lamination, etc. to make the finished blank product mechanical equipment to be calcined.

In order to ensure the normal operation of industrial equipment, the usual maintenance is also very important.

casting machineAnd the film blowing machine is not the same equipment, then what is the difference between the casting machine and the film blowing machine? In addition, the casting machine and film blowing machine factory project investment difference? The following casting machine manufacturers first from these aspects to tell us about the phenomenon of casting machine and film blowing machine, so that we can fully understand the two products:

difference of casting machine and blown film machine:

The casting machine is a professional equipment for casting film. It is mainly formed by mixing the crushed particles with adhesive, tackifier, thickener and organic solvent to make slurry with a certain viscosity. The slurry flows down from the silo and is scraped and coated on a special baseband chip with a certain thickness scraper. It is mixed and formed by drying, tackifier, thickener and organic solvent, then, according to the size and appearance of the finished product, the green embryo belt shall be subjected to production and processing such as shearing, lamination, etc. to make the finished blank product mechanical equipment to be calcined.

The film blowing machine is to melt the plastic raw materials by heating and then blow out the plastic film. There are several kinds of film blowing machine knives, including PE, POF and PVC.

Where is the difference between blown film machine and cast film process, and the difference between cast film and blown film?

casting machineThe main characteristics: the production of plastic film products out of the appearance of good smoothness, high flatness, small thickness tolerance, structural mechanics to broaden the cost-effective, good toughness, clarity than the blow molding method.

Cast film is a kind of non-stretch, non-directional flat extruded plastic film manufactured by the solution flow water quenching production, and the injection film is also a trend.

This is also the main reason for the obvious difference in the conductivity of the two plastic films.

Injection molding film because of the trend caused by carbon black, high purity graphite, etc. to produce a trend structure, in the production of directional conductivity is good, but the transverse conductivity is poor, resulting in a variety of so-called conductivity.

Because the cast film does not have a very obvious tendency, the electrical performance does not show advantages in a certain position, and the conductivity is not obvious. Another key is that there is pressure from the polishing roller to the casting film in the casting film link, which has a destructive effect on the permanent conductive filler structure (e. g. high diameter reduction), which will make the raw material lack a lot of conductivity.

The difference between the investment cost of the casting machine and the blown film machine:

The one-time investment of the hollow blow molding machine is small, the total area of the industrial plant is small, the machinery and equipment are cost-effective, and the effect of the investment is good (the equipment production cycle time is short, the equipment installation and commissioning period is short, the ancillary equipment and equipment are few, and the requirements are not high).

The one-time investment in the machine, industrial plant and equipment of the casting machine is particularly large, which is 5 to 10 times that of the blow molding method. However, the blow molding method is limited by the processing process conditions, resulting in poor product quality, small production volume, high cost of enterprise products, although continuous improvement and optimization, still can not replace the flow extension method.

casting machineThe cast film produced by the production is gradually used in the high-grade outer packaging of various objects because of its high-quality product characteristics, while the products of the hollow blow molding machine are limited to the packaging of general medium and low-grade products because of their inherent shortcomings.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

recommend News

Share