Solar Photovoltaic Film Production Line Industry Solution

Release time:

2022-07-01

At present, silicon solar cells are widely used in ground photovoltaic systems, which can be divided into monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Monocrystalline silicon and polycrystalline silicon cells are superior to amorphous silicon cells in terms of energy conversion efficiency and service life. The connection device between the solar cell array and the solar charging control device is a photovoltaic film production line composed of solar cell modules.

InPhotovoltaic film production lineThe upstream is raw materials, mainly including silicon wafers, silver pulp, soda ash, quartz sand, etc., the middle reaches are divided into photovoltaic panels and photovoltaic modules, and the downstream is photovoltaic applications, mainly used for power generation, but also alternative fuel heating.

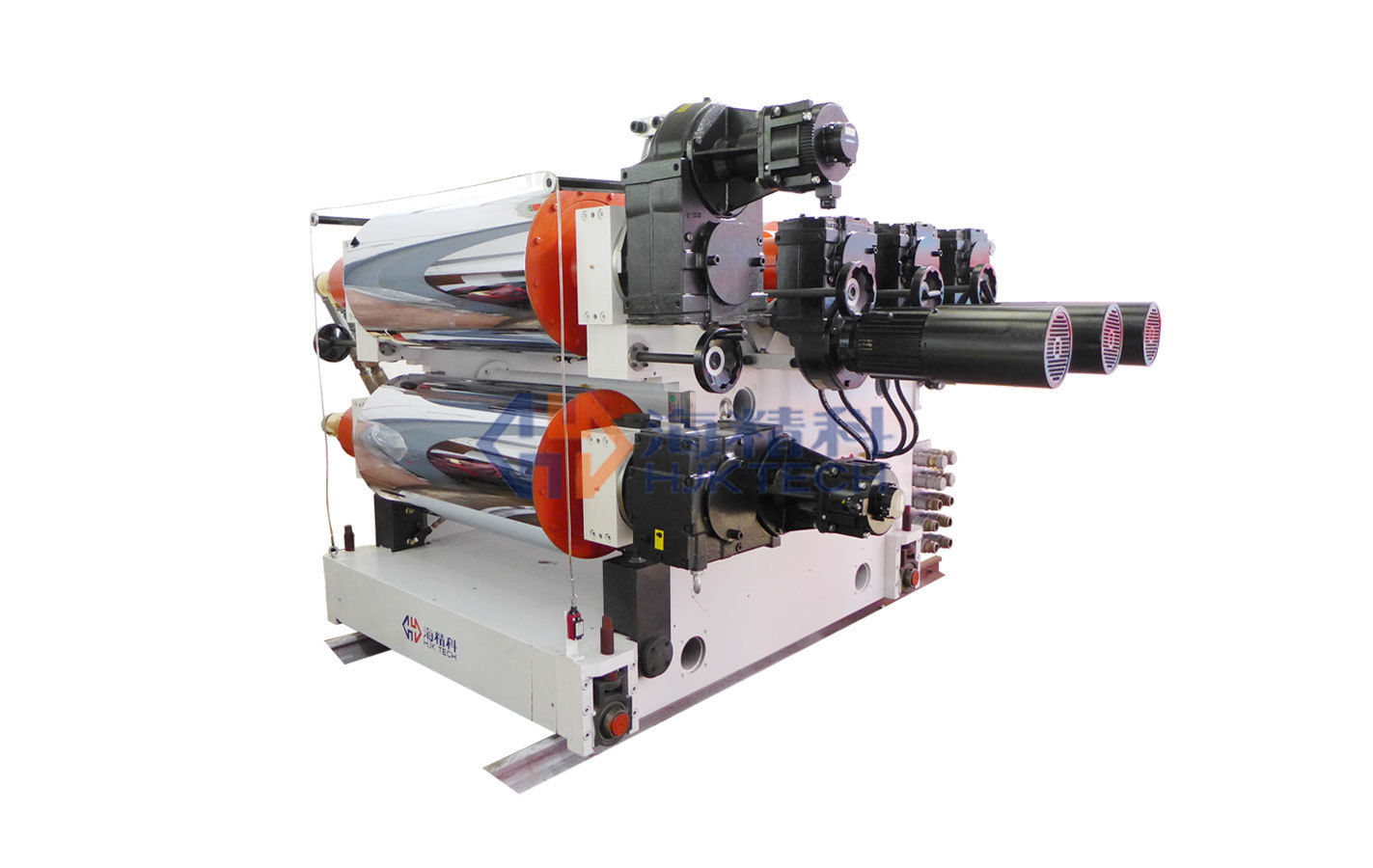

Photovoltaic film production line

Panoramic PV modules.

Photovoltaic backsheet.

Solar cell back sheet is also called solar cell back sheet film, photovoltaic back sheet, photovoltaic back sheet film, solar back sheet. In general, the photovoltaic backsheet has a three-layer structure, an outer protective layer, good environmental erosion resistance, good insulation, good inner layer and EVA adhesion. The back plate is an important part of the photovoltaic module, which is used to resist the damage of the component in the harsh environment and ensure the service life of the component.

Photovoltaic cells.

Photovoltaic cells are the core equipment that converts solar energy directly into electrical energy. At present, silicon solar cells are widely used in ground photovoltaic systems, which can be divided into monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Monocrystalline silicon and polycrystalline silicon cells are superior to amorphous silicon cells in terms of energy conversion efficiency and service life. The conversion efficiency of polycrystalline silicon is lower than that of monocrystalline silicon, but it is cheaper.

Photovoltaic welding strip.

Photovoltaic solder strip, also known as tin-copper strip, is a tin-based solder coated with a uniform thickness on the surface of a certain size of copper strip. Photovoltaic welding ribbon is used to connect the battery and the junction box, and plays a conductive role. Its performance index is closely related to the current collection efficiency of solar photovoltaic modules, the fragmentation rate of solar cells and the long-term reliability of photovoltaic modules, and it is an important material in the welding process of photovoltaic modules.

Photovoltaic glass.

Photovoltaic glass is a special glass for special related current output devices and cables. Photovoltaic glass is to seal the solar cell between the low-iron glass and the back glass, which can ensure high light transmittance, make the solar cell accept solar radiation, protect the solar cell, and extend the life.

Photovoltaic junction box.

The connection device between the solar cell array and the solar charging control device is a photovoltaic junction box composed of solar cell modules. Its main function is to connect and protect solar photovoltaic modules, so that solar cells generate current.

Photovoltaic film.

Photovoltaic film is mainly used for the packaging of photovoltaic modules and is a key material for photovoltaic modules. Photovoltaic packaging film is an indispensable core auxiliary material in the photovoltaic industry, and the demand is not affected by changes in the technical route of photovoltaic cells.

Photovoltaic film production line

The application of small blue power guide in the photovoltaic industry chain.

Linear motors need to be applied to photovoltaic silicon materials, silicon wafers, panels, components, systems and other links. The improvement of linear motor integration technology will also help the photovoltaic industry to greatly increase production capacity and reduce costs. Xiao Lan Power Guide is a new type of integrated linear motor. Using integrated structure, reducing accessories, can achieve high precision, fast, 20% price. In terms of performance, like linear motors, the price is half lower than traditional linear motors.

Can be applied to small blue power guide rail:

Photovoltaic film production line

Battery string welding equipment.

Folding welding equipment.

End welding equipment.

Solar cell handling equipment.

Solar cell marking equipment.

Automatic detection equipment for solar cells.

Solar monocrystalline silicon etching equipment.

Compared with the screw, the small blue power guide can greatly improve the performance advantages of automation equipment, more effective use of the site area, increase the output of the photovoltaic film production line industry, reduce costs, and fully meet the manufacturer's requirements for high cost performance of equipment.

Cronos SolarPhotovoltaic film production lineIndustrial solutions.

Solar cell precision machining platform.

Travel: 800*1050mm.

Reproduction accuracy: ± 1 μm.

Solar Cell Etching Platform.

Structure: upper and lower XYZ sliding table.

Travel: 900*800*30mm.

Reproduction accuracy: ± 1 μm.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

recommend News

Share