Photovoltaic Film Production Line-In-depth Analysis of Photovoltaic Film Industry

Release time:

2022-06-16

Nowadays, accelerating the development of renewable energy has become the mainstream direction of the global energy transition. The proportion of clean energy power generation has increased rapidly. Driven by cost competitive advantages, the proportion of photovoltaic power generation in the total power generation of global photovoltaic film production lines will increase from 2.4 in 2018 to 24% in 2050.

Nowadays, accelerating the development of renewable energy has become the mainstream direction of the global energy transition, and the proportion of clean energy power generation has increased rapidly.Photovoltaic film production lineThe proportion of photovoltaic power generation in total power generation will increase from 2018.2.4%Raise2050of the year24%Level.

With the strong growth of the installed capacity of the photovoltaic film production line, the domestic photovoltaic industry ushered in a major development opportunity, providing a broad growth space for the photovoltaic industry chain segment.

In the photovoltaic film production line, photovoltaic film is mainly used for the packaging of photovoltaic modules, which is the key material of photovoltaic modules. Photovoltaic module structure: Source: "Research Progress of EVA Adhesive Film for Photovoltaic Module Encapsulation"

The adhesive film is placed between the module tempered glass or backplane and the solar cell to encapsulate and protect the cell. It is mainly used to wrap on both sides of the battery and play a buffering role between the battery and the glass (or back plate).

Because the photovoltaic cell itself is easily broken, and the packaging process is irreversible, and the operating life of the battery module is usually required to be more than 25 years, once direct contact with rain, snow, sand and dust will seriously affect the photoelectric conversion efficiency of photovoltaic cells. Therefore, although the proportion of film materials such as adhesive film in the total cost of photovoltaic modules is not high, it is a key factor in determining the quality and life of photovoltaic modules.

FromPhotovoltaic film production lineIn terms of the size of the film market, the market space of the photovoltaic film link in 2020 is about119Billions of dollars.2021Since the beginning of the year, the photovoltaic film market space has grown rapidly, mainly due to the rapid growth of photovoltaic demand in the era of parity, upstream.EVAParticle price increase+The increase in gram weight led to a corresponding increase in the price of photovoltaic film.

Photovoltaic film production line film upstream material

At present, the market packaging materials are mainly transparent EVA film, whiteEVAAdhesive film, polyolefin (POE) Adhesive film, co-extruded polyolefinPOE(EVA-POE-EVA) Film and other packaging film (includingPDMS/SiliconAdhesive film,PVBAdhesive film,TPUglue film) and so on.

Photovoltaic film production line EVA film is the main core packaging material required in the production process of photovoltaic modules.EVAThe resin is vinyl-Vinyl acetate copolymer. AccordingCPIA,2020In the year, the component packaging material is still transparent.EVAAdhesive film mainly, accounting for about56.7%market share.

WithPhotovoltaic film production lineManufacturers are paying more and more attention to the role of packaging materials in improving power generation efficiency, high quality film (white efficiency EVA film, multi-layer co-extrusion.POEThe proportion of adhesive film) is gradually increasing, while the use of double-sided batteries and double-glass components has further promoted the market share of high quality adhesive film.

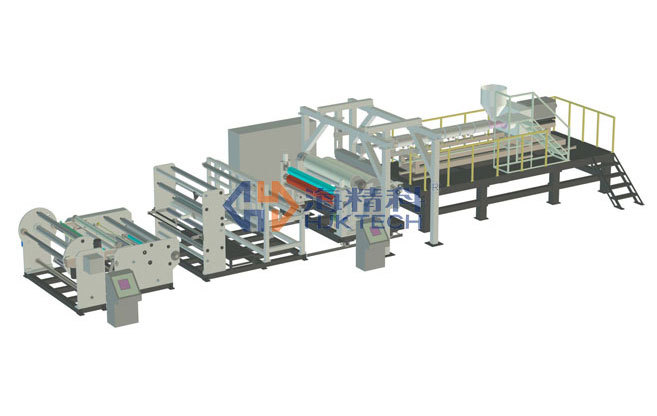

Pay attention to Haiceike to learn more. Haiceike Machinery is an innovative technology enterprise integrating R & D, manufacturing, sales and service. It specializes in the development of plastic sheet machines, film machines, and casting machines, and provides users with plastic packaging machinery Complete set of solutions. Welcome to inquire.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

Next Page

recommend News

Share