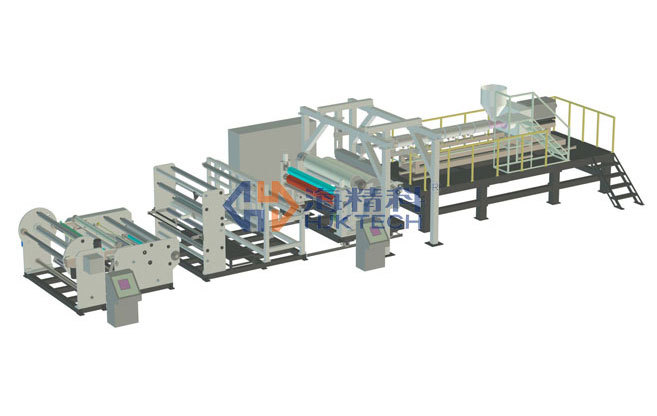

Photovoltaic Film Production Line-New Photovoltaic Film Material

Release time:

2022-06-22

The important material used in the production of photovoltaic modules in the photovoltaic film production line is photovoltaic film, which is used to produce photovoltaic modules to protect the batteries inside the modules. According to the different product structure, it is divided into EVA film, POE film and so on. The encapsulation film plays a role of wrapping and bonding in photovoltaic modules, and the POE film has better encapsulation performance and is widely used in double-sided modules.

1, photovoltaic film background introduction

Photovoltaic film production lineThe important material used in the production of photovoltaic modules is photovoltaic adhesive film, which is used in the production of photovoltaic modules to protect the cells inside the module. According to the different product structure, divided into EVA film,POEMembrane, etc. The encapsulation film plays a role of wrapping and bonding in the photovoltaic module,POEThe film has better packaging performance and is widely used in double-sided components.

In 2019, China's packaging film market demand is about.10.8billion square meters.EVAAdhesive film,POEAdhesive film is the mainstream packaging material at present, accounting for about97.1%which is transparent.EVAAdhesive film, whiteEVAAdhesive film,POEThe market share of the adhesive film is respectively.69.6%,15.5%,12.0%. As photovoltaic film production line manufacturers pay more and more attention to the role of packaging materials in improving power generation efficiency, high quality film (white efficiencyEVAAdhesive film, multi-layer co-extrusionPOEThe proportion of adhesive film) is gradually increasing, while the use of double-sided batteries and double-glass components has further promoted the market share of high quality adhesive film.

2, Saiwu technology

Saiwu Technology Focuses on POE Film2018 In the field of photovoltaics, the company has Tianhe, Jingao, Longji, Jinko, Artes, Oriental Risheng, Tongwei, Hanhua.Q-Cells,TATA,Value,VictramSharp, Panasonic and other head enterprise customers. Photovoltaic film production line Photovoltaic film field production capacity of the world. Company2019 Continued to expand sincePOEAdhesive film production capacity, the current production capacity has reached3.5yiping,2021 Annual shipments are expected to reach2.1Yiping, a major source of revenue for the company.2020 YearPOEPackaging adhesive film (includingEPE) the market share17.5%, more2019 AnnualPOEPackaging adhesive film (includingEPE)9.05%The market share has risen.8.45percentage point. Company annual production2.55Billion square meters of packaging film production line in Pujiang, Zhejiang Province, successfully started construction, part of the production line equipment from2021Q2Commissioning was completed and put into production.

As of June 2021,Photovoltaic film production linePhotovoltaic backsheet production capacity reached monthly average1500 Ten thousand square meters, photovoltaic packaging film production capacity reached the monthly average.1200 Ten thousand square meters.

Photovoltaic film production lineThe packaging film to EVAPOE as the mainstream, the future.POEThe proportion of products is expected to increase30-40%.

As of the end of 2019, the Company's film production capacity is approximately1.4billion square meters,2020 Year-end approx.2.4Billion square meters, the company intends to raise ji funds6 Billions of dollars, of which3.45Billions of yuan for annual production1.7100 million square meters of polymer special membrane technology transformation project. PV film production line PV film gross margin is17.37%. Pay attention to Haiceike to learn more. Haiceike Machinery is an innovative technology enterprise integrating R & D, manufacturing, sales and service. It specializes in the development of plastic sheet machines, film machines, and casting machines, and provides users with plastic packaging machinery Complete set of solutions. Welcome to inquire.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

recommend News

Share