Heating steps of casting machine?

Release time:

2022-09-06

The heat-up step of the casting machine cannot be completed in one step. Just complete the following operations, adjust the correct working position, and carefully complete all operations. Pass the film through each roller, then turn off the cooling roller and squeeze the film, then the casting machine heating step?

Heating steps of casting machine?

The heat-up step of the casting machine cannot be completed in one step. Just complete the following operations, adjust the correct working position, and carefully complete all operations. Pass the film through each roller, then turn off the cooling roller and squeeze the film, then the casting machine heating step?

Heating steps of casting machine?

1. After the production is completed, manually adjust the casting machine to the non-working position, and then introduce the material into the receiving tray to stop the casting machine.

2. Start the casting machine, check whether the thick slab and the melt are stuck flat, and then tighten the thick slab at the outlet towards the personnel. Check whether the rotation and pressure of each roller of the casting machine are normal, and whether the heat exchange system, pump and pressure gauge can work normally.

3. In various large industrial machines, the casting machine is widely used. Different manufacturers and different casting machines use different page tours, which are large and small and more practical. If there is no correct operation method, it will bring great inconvenience to production, and even bring safety hazards to the staff. Therefore, it is necessary to understand the correct operation method of the casting machine.

4. After buying the casting machine, the first thing to do is to understand the product specifications in detail. Most mechanical equipment will have some special, professional operating terms and procedures, these terms and procedures in our daily lives rarely or even see. So it is helpful to have a careful understanding of the 5. product specifications. Understanding the basic functions and control operation of the machine is the basis for using the casting machine.

What areas can the casting machine be used in?

1. The casting machine also has the characteristics of high production line speed, stable performance, environmental protection and energy saving. The thickness of the product is 0.017-0.08mm (calculated according to the international standard of 0.025mm). It's a year of skyrocketing filmmaking. Therefore, the market demand for casting machines is increasing. Demand is expected to continue to increase in the coming years. Therefore, the market for casting machines is very broad.

2. On this basis, some insiders predict that with the increase of streaming media movies and projects under construction, the production capacity of streaming media movies may be temporarily surplus in 2021, so a new round of price war is imperative. If this prediction becomes a reality, in order to avoid vicious competition in the market, tape processing enterprises should take the road of independent innovation and develop differentiated and specialized products. Another important link is the rational selection of equipment and its suppliers.

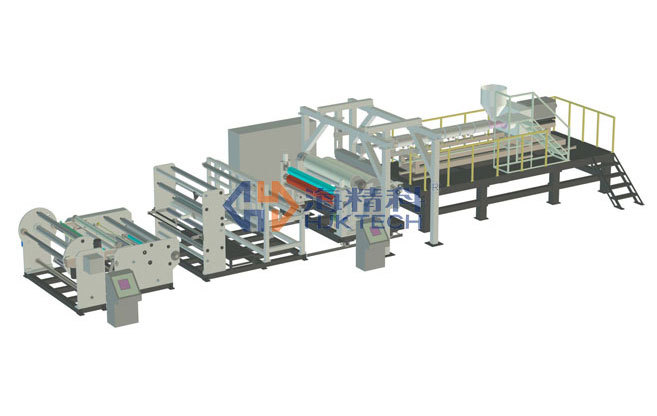

3. The design of the casting machine can continuously send the adjusted casting material to the casting section. The main components of the pouring section are pouring head, pouring table, wire mesh, load-bearing belt or steel belt. The casting head can be a slit die, a coating roller, an adjustable scraper or a node rod, all of which are precision machined with a machining tolerance of less than 1 micron. The replacement of the casting table can also be high-precision plates, such as granite, with a roughness of 1% mm.

Waterproof breathable membrane production line, CPP casting machine, cast film machine, breathable membrane machine, geomembrane equipment manufacturer, waterproof board equipment manufacturer. The company's technical team has rich experience, strong research ability, stable and reliable equipment, excellent indicators, high flexibility, and has been recognized and praised by the majority of users. On the way forward, Zhu Long people always adhere to the quality of casting faucets from production to customers.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

Previous Page

Next Page

recommend News

Share