What is the operation skill of the casting machine?

Release time:

2022-09-15

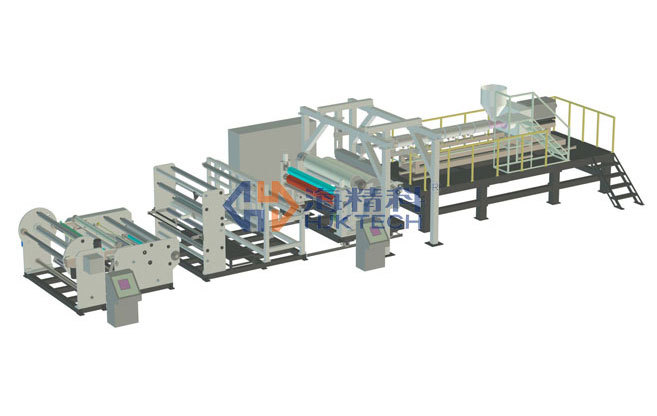

In various large industrial machines, the casting machine is widely used. Different manufacturers and different casting machines use different page tours, which are large and small and more practical. If there is no correct operation method, it will bring great inconvenience to production, and even bring safety hazards to the staff. So what is the operation skill of the casting machine?

What is the operation skill of the casting machine?

In various large industrial machines, the casting machine is widely used. Different manufacturers and different casting machines use different page tours, which are large and small and more practical. If there is no correct operation method, it will bring great inconvenience to production, and even bring safety hazards to the staff. So what is the operation skill of the casting machine?

What is the operation skill of the casting machine?

1. After buying the casting machine, the first thing to do is to understand the product specifications in detail. Most mechanical equipment will have some special, professional operating terms and procedures, these terms and procedures in our daily lives rarely or even see. So it is helpful to know the product specifications carefully. Understanding the basic functions and control operation of the machine is the basis for using the casting machine.

2. Adjust the correct working position and complete all operations carefully. The film was passed through each roll, then the chill roll was turned off and the film was squeezed. Prepare relevant tools, such as copper sheet, alcohol, release agent, etc. After the production is completed, manually adjust the casting machine to the non-working position, then introduce the material into the receiving tray and stop the casting machine.

3. Start the casting machine, check whether the thick plate and melt are stuck flat, and then tighten the thick plate towards the exit personnel. Check whether the rotation and pressure of each roller of the casting machine are normal, and whether the heat exchange system, pump and pressure gauge can work normally. Check whether the die, roller and its surroundings of the casting machine are clean, and then clean the die with alcohol, paraffin and gauze, or clean with copper sheet and spray release agent.

4. After the production is completed, manually adjust the casting machine to the non-working position, and then introduce the material into the receiving tray to stop the casting machine. In the process of use, we should also pay attention to some details, such as water stains around the casting machine. Because water can conduct electricity, and the casting machine itself is a live product, it is necessary to prevent leakage accidents. In order to ensure the normal operation of mechanical equipment, daily maintenance is also essential.

What are the composition and categories of the casting machine?

1. What does the casting machine do? The production of cast film is the process of making cast film. Friends ask again, what is cast film? Cast film is a flat extruded film produced by melt casting quenching, without stretching and orientation. There are two ways of single-layer and multi-layer co-extrusion casting. With excellent heat sealing performance and excellent transparency, it is one of the composite substrates for packaging.

2. The casting machine was introduced into China from abroad in the 1980 s, and most of them are single-layer structures. For the production of high temperature cooking film, vacuum aluminum film, etc.

3. There are two types of casting: solution casting and melt casting. The main components of the casting machine are: the nozzle for the smooth outflow of liquid, the steel belt for film formation and the drying system. The film thickness depends on the viscosity of the liquid, the feed rate and the vehicle speed. The accuracy of the film mainly depends on the accuracy of the nozzle and the steel strip. Of course, the stability of equipment operation is also an important factor affecting product quality. High-precision electronic ceramic casting machine uses alumina as the main raw material for ceramic casting. The pulverized powder is first mixed with a binder, a plasticizer, a dispersant and a solvent to prepare a slurry with a certain viscosity. The slurry flows down from the hopper and is coated on a special base tape of a certain thickness with a scraper. After drying and curing, the film of the green tape was peeled off from the top. Then according to the size and shape of the finished product, the green belt is perforated, laminated, etc. to manufacture the finished product to be sintered. It has the advantages of low cost, high quality, non-toxic and simple production process.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

Previous Page

Next Page

recommend News

Share