Development Trend of Sheet Machine

Release time:

2022-10-25

In the sheet metal production line of single extrusion configuration, it has the advantages of energy saving, material saving, uniform plasticization, etc., can produce a variety of materials, and the price is not expensive. This kind of sheet material with "Chinese characteristics" should be vigorously promoted and continuously improved.

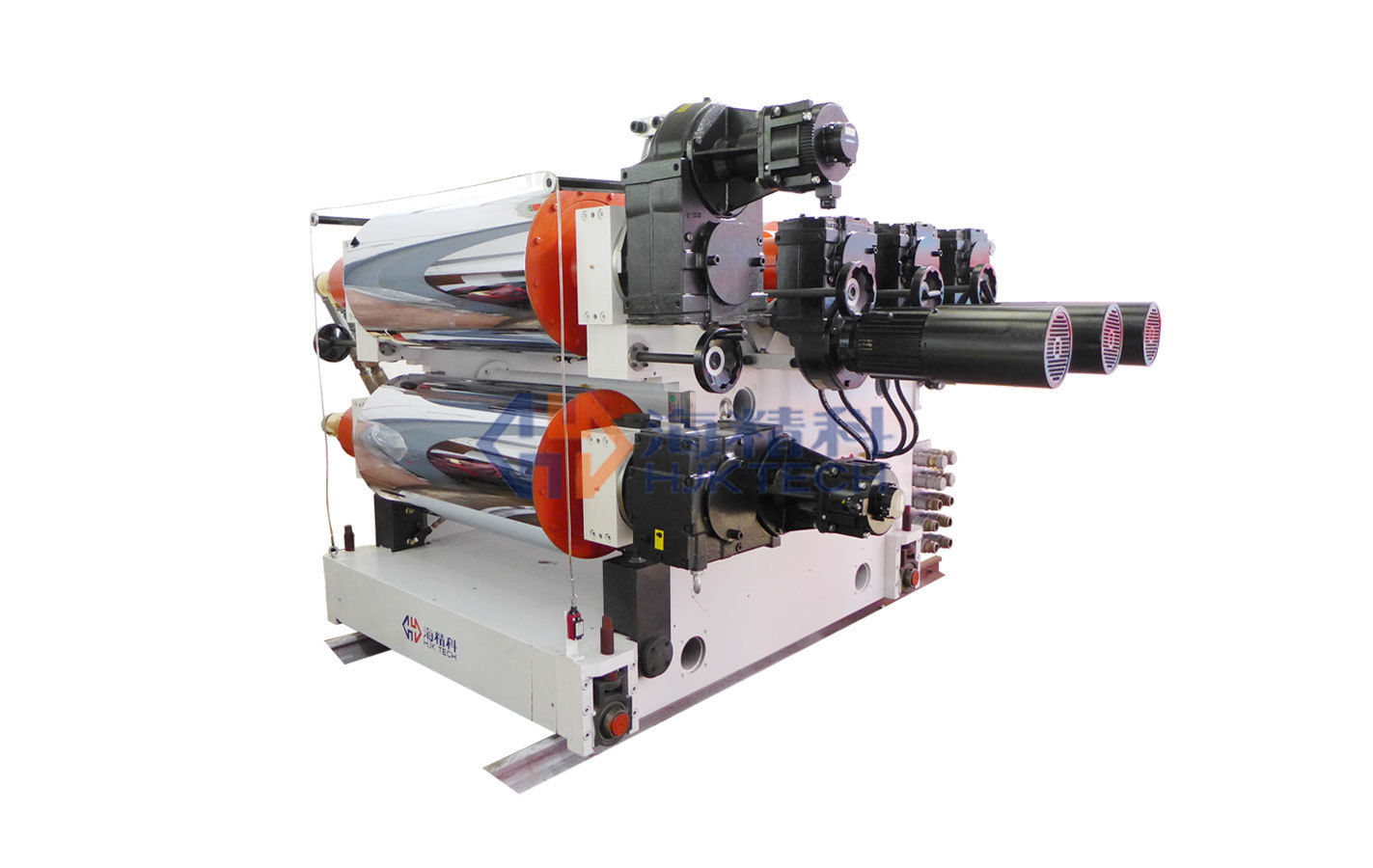

sheet machineMainly used in the production of disposable plastic cups, plates, bowls, plates, boxes and other thermoforming products, sheet machine is widely used in food, vegetables, fruits, beverages, dairy products, industrial parts and other fields of packaging. With the continuous growth of domestic demand, the application of packaging plastic thermoforming sheet is more and more extensive, and the consumption is also increasing year by year, and the prospect is good.

The production of plastic sheet machine is a commonly used calendering method, which is mainly used for the production of PVC and PVDC sheets; the other is extrusion method, which is used for the production of BOPS, EPS, PET, PP, HIPS and other sheets. In the past ten years, sheet metal production and sheet metal machinery manufacturing enterprises have cooperated with each other and introduced together, which has also improved the overall development level of the plastic sheet metal industry. New plate processing technology, new raw and auxiliary materials in the advanced equipment configuration to give full play.

The gradual improvement of the domestic plate manufacturing level has promoted the increase of domestic plastic plate production enterprises and the diversification of plate varieties, and also promoted the unprecedented prosperity of the thermoforming packaging industry. The development of China's chip machine industry has the following trends.

First, the "vertical three-roll" sheet production line configured with a single "separate single screw extruder" tends to be saturated. Most domestic thermoforming enterprises have this type of sheet production line, which has made great contributions to the early market occupation, accumulation of funds and development of technology. The plates it produces can basically meet the production requirements, but the plates it produces, especially HIPS plates, cannot produce satisfactory gloss and low grade.

This kindsheet machineThe technology is quite mature, the assembly is convenient, the parts are easy to buy, the configuration is simple, the operation is simple, the price is cheap, and the maintenance cost is low, and it has become a more popular model. Intense competition has forced some sheet metal machine manufacturers to turn to other products. This machine can process PP, HIPS, PE egg disc, blister tape packaging sheet, etc. If an air knife is used instead of a press roll, a much thinner sheet with blisters can be produced. However, most of the domestic equipment is not equipped with this device, which brings a lot of inconvenience to the production enterprises and restricts the development of enterprises in the field of sheet metal forming products to a certain extent.

In the sheet metal production line of single extrusion configuration, it has the advantages of energy saving, material saving, uniform plasticization, etc., can produce a variety of materials, and the price is not expensive. This kind of sheet machine with "Chinese characteristics" should be vigorously promoted and continuously improved, equipped with advanced follow-up equipment and control system, introduce our own advanced production line in China to the world, and get rid of the development state of "changing with people.

Equipped with a single "vented-double-stage single-screw extruder"sheet machineIt is a new type of sheet production line launched by equipment manufacturers with the aim of "environmental protection. This type of sheet production line can process high-filled PP/PE sheets, lightweight/biodegradable sheets and biodegradable sheets. However, domestic "degradable plastics" are not "completely degradable materials", and how many contain "plastic" components. In addition, the proliferation of a variety of "degradation materials", the existence of the phenomenon of fish-eye mixed beads, coupled with the competition of "pulp forming products.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

Previous Page

recommend News

Share