What is the use of the sheet produced by the PET sheet production line?

Release time:

2022-10-20

PET sheet production line is used to produce PET transparent sheet products, which is an important food packaging material with high transparency. What is the use of PET sheet? PET sheet is a new type of plastic product developed in recent years

PET Sheet Production LineWhat is the use of the sheet produced?

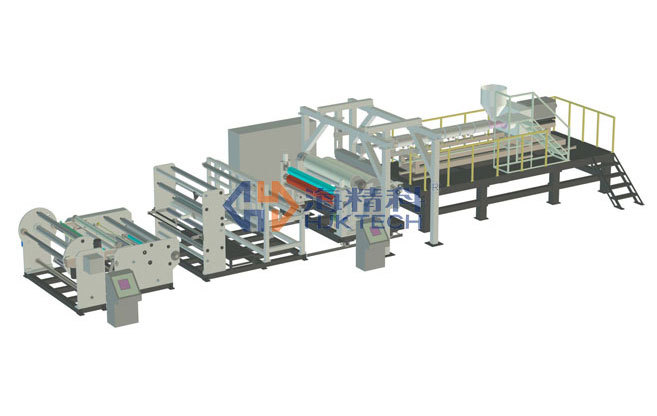

PET Sheet Production Line

PET Sheet Production LineUsed in the production of PET transparent sheet products, is an important food packaging materials, with high transparency characteristics. PET sheet is a new type of plastic products developed in recent years. What is the difference between it and traditional plastics? PET sheets are more complicated in the production process. It is produced mechanically through a series of compression polymerization processes. Generally speaking, this plastic is a material similar to translucent, but the transparency can be changed in real time by its specific practical requirements. So what is the PET sheet used in the PET sheet production line?

PET sheet production line PET sheet can be made into foam through a special compression method at the same time, and a large amount of gas can be filled between the two layers of material. After forming, the molecular structure of this material becomes extremely stable, and it is not easy to deform even under the impact and extrusion of gravity. It is generally used in the express delivery industry to protect express goods.

PET sheet production line light transmission sheet is a thermoplastic green environmental protection plastic products. The PET light-transmitting sheet has good brightness and high-quality transparency after production and processing. PET light sheet products are mainly characterized by easy processing; biodegradable; high transparency; no water line; excellent thermoplastic; non-toxic, hygienic, safe and reliable, can be used for food, medical equipment packaging. PET light transmission sheet is mainly used in plastic, folding box, printing, window, panel, advertising supplies, widely used in food packaging, toy gift packaging, hardware tools packaging, advertising printing packaging, electronic product packaging, clothing templates, tags, etc.

For the production of sheetPET Sheet Production LineMaybe many people want to know how it is composed? So today we will tell you what is the composition of the production line? First, the crystallization drying system, this system has a single screw and twin screw, twin screw is better, both quality and durability are much stronger than single screw, so we recommend that you choose twin screw as much as possible. In addition, there are extruders, hanger molds, three-roll calender, cooling racks, and double-station winder. These accessories form a completed production line.

Good production lines produce La Drop. This material is highly stretchable, making it reassuring when in use. After the later nano-molecular technology treatment, it looks like a thin film, but due to the stability of its internal molecular structure, it can provide good protection and isolation. More importantly, it has better transparency and smoothness, good display effect, excellent surface decoration performance, can be printed without surface treatment, easy to press patterns, easy to metallize, and has good mechanical strength.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

Previous Page

recommend News

Share