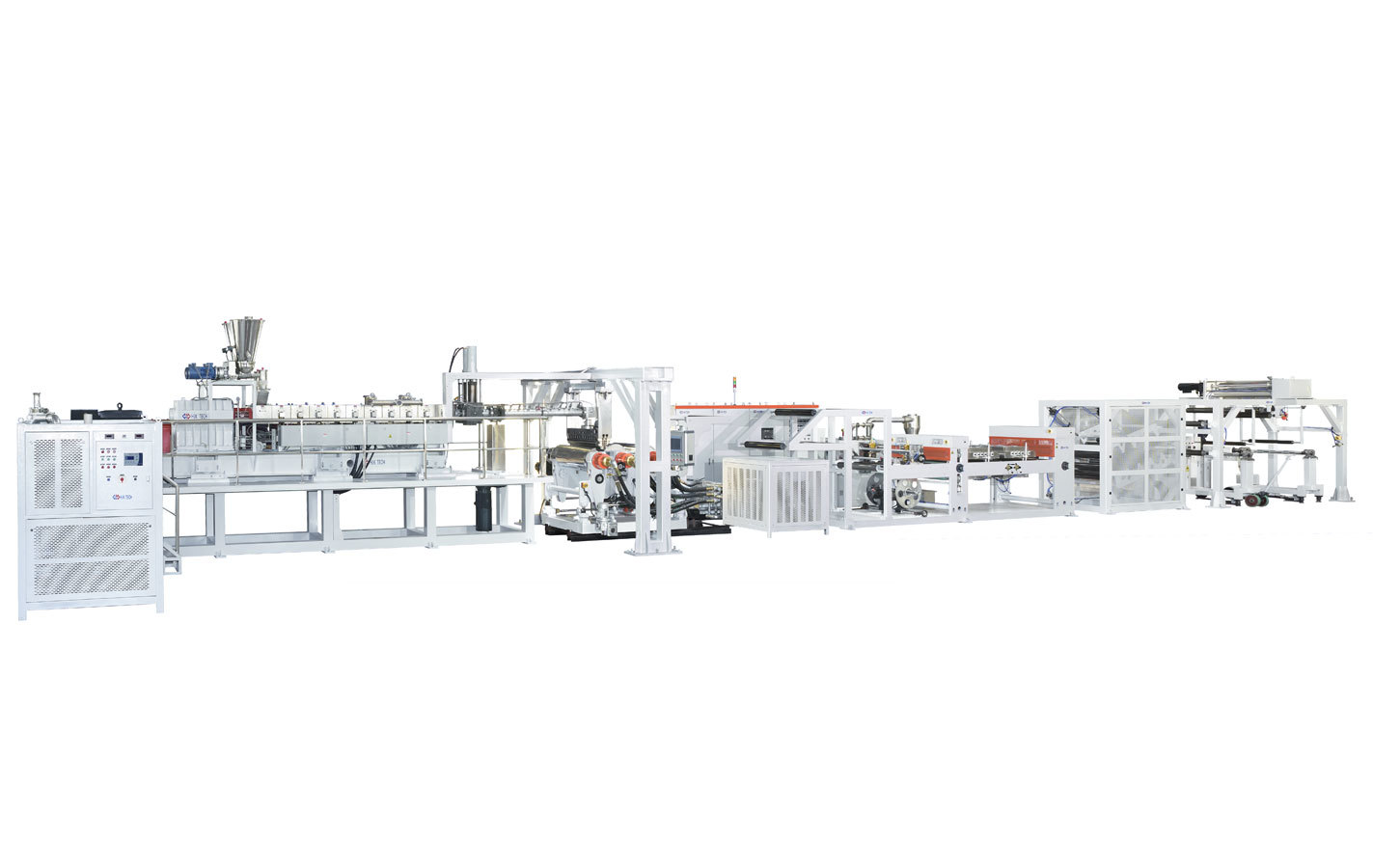

PET sheet production line daily maintenance in place, longer service life

Release time:

2022-11-24

Before each factory operates the PET sheet production line, the staff need to be trained, especially in some large ICBC, because there are many people and the equipment is used in streamlined operations, so problems are often not easy to solve and may affect our work efficiency. In fact, such a production line only needs to do daily basic maintenance work, and it is very easy to avoid some problems. Such daily basic maintenance and cleaning have a certain importance, we can not ignore.

Every factory operationPET Sheet Production LineIn the past, the staff needed to be trained, especially in some large ICBC, because there were many people and the use of equipment was streamlined, so problems were often not easy to solve and might affect our work efficiency. In fact, such a production line only needs to do daily basic maintenance work, and it is very easy to avoid some problems. Such daily basic maintenance and cleaning have a certain importance, we can not ignore.

PET Sheet Production LineThe Importance of Daily Basic Maintenance

1. Avoid the accumulation of debris affecting the use of the production line.

The PET sheet production line will definitely leave some debris. Problems should be dealt with in a timely manner. It is recommended that the production line be cleaned as a whole every day, and it should be implemented on people's heads to avoid some problems. Such a production line may have some material residues in daily production. If there is any problem, it will cause serious wear and tear, so do a good job of cleaning every day.

2. Effectively check the production line and deal with problems in time.

Because the PET sheet production line has certain wear and tear, no matter what kind of parts have such problems, we need to carry out follow-up processing and inspection in time. If the cleaning can be carried out carefully every day, in fact, the staff will probably know what kind of problems the equipment has now, report the failure in time and carry out maintenance in time, then the subsequent serious failure will naturally not occur. I believe that as long as it can be handled in time, the use of the production line will not be affected.

Basically, large PET sheet production line manufacturers provide customized services, of course, there are manufacturers have in stock. If we want to make a basic production line, we must choose a high-quality manufacturer. After all, it is impossible to frequently customize different types of production lines. It is definitely better to choose high-quality manufacturers to cooperate. Customization is guaranteed, and there is no need to worry about subsequent use. However, when you buy a production line, you must determine its practicality. For the practicality of PET sheet production line, attention should be paid to customization.

First of all, the quality of the production line must be confirmed in advance.

No matter what type of PET sheet production line we want to purchase, quality confirmation work is required. Only in this way can the subsequent use effect be truly guaranteed. And everyone must be clear that the quality of the production line is high and the price will not be too low, so the quality of the production line must be confirmed. If you can really find high-quality manufacturers to cooperate, then it must be to make its production line quality better, as far as possible and regular manufacturers to cooperate better.

PET Sheet Production LineCustom requirements must be clear.

When customizing the PET sheet production line, you must be clear about your needs, and you also need to inform the manufacturer of the function and performance of the production line in advance. Because of the different types of production lines, customization will be very different. Overall comparison is recommended.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

recommend News

Share