Precautions for the casting machine

Release time:

2023-01-04

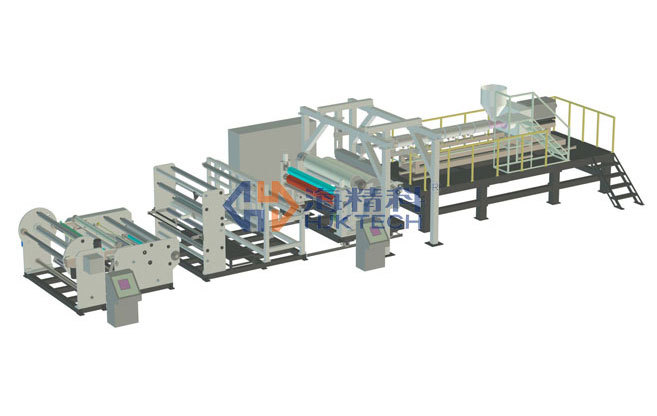

The development prospects of the industry is very good, because in the use of the benefits for the enterprise more, so by the customers, in order to let you more of it, then we will talk about the matters needing attention of the casting machine.

casting machineThe development prospects of this industry is very good, because in the use of the benefits for the enterprise more, so by the customers of all ages, in order to let you more of it, then we come to talk about the matters needing attention of the casting machine.

Now there are many peoplecasting machineSome of the basic information is not understood, so as a manufacturer, we also need to briefly explain, in fact, this casting machine in the process of use, to ensure that the equipment and the surrounding environment clean and tidy, in line with the site "5S" requirements. Turn on the main power switch of the equipment and power on the equipment. Next, our CIA can turn on all the knob switches on the control cabinet panel, and each temperature zone will start to heat up. The heating is segmented heating. Pay attention to check whether the temperature and instrument in each area are normal, and set the temperature control instrument parameters according to the process requirements. If there is any abnormal phenomenon, the relevant personnel should be notified immediately, and the temperature should be raised after treatment. When all temperatures reach the set temperature, heat preservation for 30 minutes to boot. When using the casting machine, it is important to check whether the water and gas system is normal before starting up. Check whether the cooling water tower, refrigerator, oil temperature machine, edge cutting machine and edge material blower are normal, and start up in turn. Check the readiness of production materials.

The casting machine opens the operation interface of the equipment console. Then start the screw in turn to carry out the film surface punching machine. Gradually increase the screw speed, and observe the current change during acceleration. After forming, start the whole machine speed control system for membrane transmission. When the film is worn, the transmission should be carried out at the roller position, avoiding the roller surface. After the membrane penetration is completed, the edge material is cut and crushed. Control the feeding speed when the edge material is broken, and do not wear gloves when operating. After these steps are completed, the thickness gauge can be opened to adjust the film surface, and the product can be coiled after the adjustment is completed. In the production process, it is necessary to observe the changes of temperature, pressure, and current at all times, and find abnormalities and problems in time. During the operation of the casting machine, it is necessary to check whether the rotation and pressure of each roller of the casting equipment are normal, whether the heat exchange system, pump and pressure gauge can work normally, etc., put each roller on thick film, and then the cold hard roller is in a closed state, and press the diaphragm. Or you need to check whether the thick film and melt are flat and smooth after opening the thick film casting machine, and then fix the thick film towards the outlet of the worktable.

After the introduction of the above content, we are also right.casting machineThe matters needing attention have further understanding. When I see him again in the future, I will not feel strange, and there will be no frequent problems in the process of using it. Well, that's all for today's content. I believe it will bring more wonderful knowledge points.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

Previous Page

Next Page

recommend News

Share