What are the advantages of the casting machine?

Release time:

2023-01-13

The casting machine is also very common in our life. Because its advantages are more prominent, there are more people who choose to use it. Today, I also use this opportunity to introduce the advantages of the casting machine for everyone? If you want to know, take a look at it.

casting machineOf course, we are very common in life. Because its advantages are more prominent, there are more people who choose to use it. Today, I also use this opportunity to introduce the advantages of the casting machine for everyone? If you want to know, take a look at it.

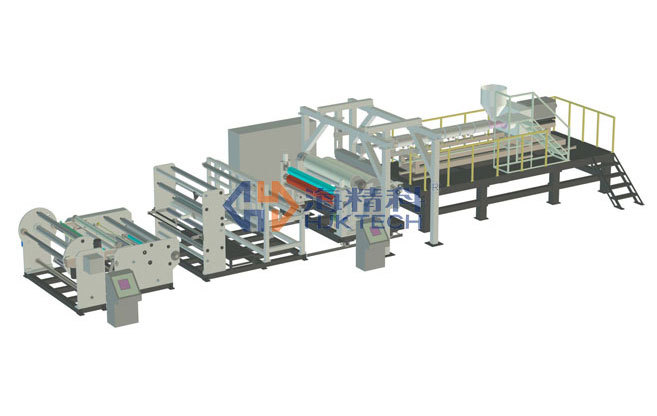

We are usingcasting machineThere is a lot of basic information to know before, after all, there are a lot of knowledge points involved. For example, the main function of the casting machine is to eliminate impurities in the melt and improve the physical and chemical properties of the cast film. In fact, it is also called squeeze casting compound machine, which is a high degree of automation, simple operation and fast production speed. It was first used in the United States and Europe and developed well. In recent years, it has been gradually applied in our country. Has gradually replaced the dry mix hot melt adhesive coating machine. In daily life, the casting machine should be maintained to achieve the effect of long service life. Now the equipment is mainly used in papermaking, coatings and plastics and other fields. It is a molding technology with a long history, mainly including slurry preparation, ball mill mixing, molding, drying, gluing, sintering and other processes. Compared with other molding processes, the casting machine has the advantages of simple equipment process, continuous production, small product defects, uniform performance and high production efficiency. Now its relatively large features are very suitable for the preparation of ceramic parts from large sheets, which is difficult to achieve by pressing or extrusion molding processes.

casting machineThe performance requirements are mainly reflected in the accuracy of the control. It mainly includes liquid level control, scraper film formation, steady speed, atmosphere control, temperature heating, smooth transmission of film belt, celadon belt cutting, etc. For example, level control is a key factor affecting the thickness of castings. It is required that the height of the liquid level changes little, otherwise the thickness of the billet porcelain belt changes greatly along the casting direction, even out of tolerance. Usually the liquid level changes within 0.5mm, the thickness of the celadon belt will not change. We also saw that the height of the liquid level was manually controlled in the past, and the liquid level often fluctuated, resulting in unqualified thickness of celadon strips in the casting direction and uneven thickness. This is obviously related to the level of operation and responsibility of workers. The liquid level control is changed to automatic control, the liquid level height is measured by ultrasonic, and the flow is controlled by a solenoid valve. The consistency of the billet thickness is significantly improved. Its speed stability has a significant effect on the thickness of the casting. In the past, DC motors were used, so the speed was slower during peak electricity consumption. Most units do not use power after get off work, so the walking speed is accelerated, which causes the thickness of the casting machine to change on the way to and from get off work, resulting in unqualified products. After replacing the casting machine with a variable frequency motor, the running speed is obviously stable and the thickness consistency is improved. If you don't know, then come and have a look. That's all about this knowledge. I hope I can help you.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

recommend News

Share