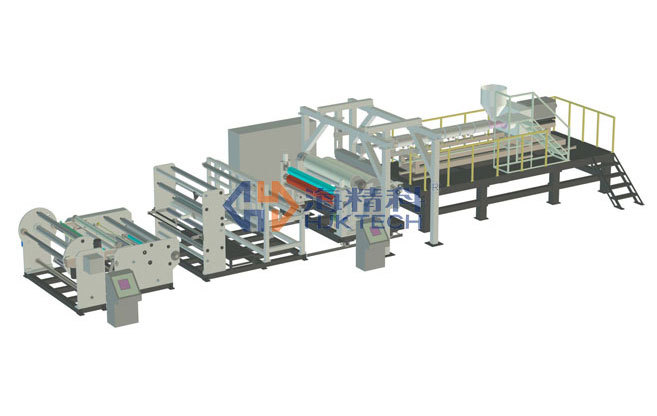

Construction of high efficiency green environmental protection pe casting machine

Release time:

2023-01-23

The structure of high efficiency green environmental protection pe casting machine includes casting machine body, base, support leg, baffle, cylinder, moving block, support point strip, limit slot, limit plate, limit frame, anchor bolt, cast-in-place plate, support frame, purification treatment box, centrifugal fan, air inlet, air inlet, gas pipeline, connecting sleeve, steel sleeve, limit plate, assembly block and activated carbon filter plate, it can handle the problem that the height of most high-efficiency pe casting machines cannot be adjusted and there is no ash and odor removal function.

Now a lot of plastic film production and processing will use high efficiency pecasting machineHowever, most of the high-efficiency casting machines currently on the market still have some problems with low applicability. For example, if there is no ash and odor removal effect, it will cause adverse effects on the surrounding staff. In addition, the height of the PE casting machine is generally unchanged. When feeding, the discharge port of the casting machine must face the discharge port of the transportation device. Because the height is not enough, it usually requires manual adjustment. There is a cushion block under the casting machine, which is more troublesome and reduces the high efficiency to a great extent, which is not beneficial to the application.

Therefore, the manufacturer has developed the advantages of adjustable height and ash and odor removal, which overcomes the fact that most high-efficiency pe casting machines cannot be adjusted in height and have no ash and odor removal.

High efficiency plastic filmcasting machine

the structure of high efficiency green environmental protection pe casting machine includes casting machine body, base, support leg, baffle, cylinder, moving block, support point strip, limit slot, limit plate, limit frame, anchor bolt, cast-in-place plate, support frame, purification treatment box, centrifugal fan, air inlet, air inlet, gas pipeline, connecting sleeve, steel sleeve, limit plate, assembly block and activated carbon filter plate, it can handle the problem that the height of most high-efficiency pe casting machines cannot be adjusted and there is no ash and odor removal function.

High efficiency green environmental protection PE casting machine can also be used as a support base by setting the support leg. Baffles can be set to facilitate cylinder installation. A support point strip can be provided, which can function as a support point base. Limit slot and limit frame can be set to limit the adjustment scope of the casting machine theory. A limit plate can be set to avoid the separation of the limit frame and the limit slot. A support frame can be set, which can play the role of supporting the cast-in-place board. An air intake mask can be set to increase the scope of the air intake. A connecting sleeve and a reinforcement sleeve can be provided to limit the efficacy of the limit plate. Activated carbon filter plate can be set to purify and treat the vapor. An opening can be set to facilitate assembly of the assembly block. Screw holes can be set to facilitate the application of assembly blocks.

In all kinds of large industrial machinery, large and medium-sizedcasting machineThe application of the casting machine is very wide, and there are some differences in the use of different types of casting machines. For example, there are certain differences in the application of small and medium-sized casting machines and various types of casting machines. If there are no correct operation steps, it will cause great harm to productivity, and even pose a threat to the safety of operators. Therefore, it is very necessary to master the correct usage of casting machines. Thank you for reading and I hope my sharing will be helpful to you.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

recommend News

Share