Common problems in PET sheet production line

Release time:

2022-09-26

Common problems in the PET sheet production line, we use medium and high density substrates to process PET sheets into various lines, and then foam, various matte flowers, different colors and textures of PET sheets, the variety is very rich, and it is dazzling in the market. Of course, all products may have different characteristics.

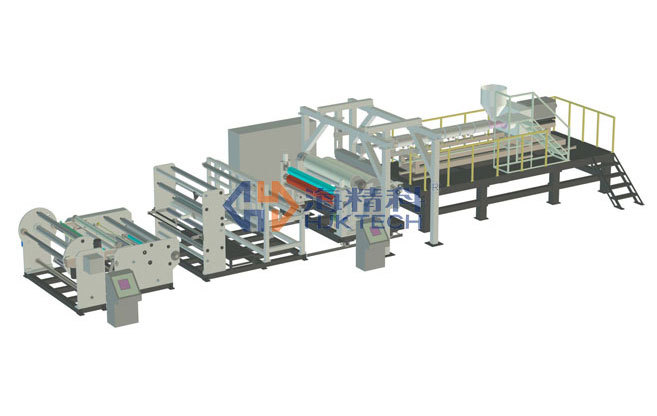

PET Sheet Production LineCommon problems in

We use medium and high density substrates to process the PET sheet production line into various lines, and then foam, various matte flowers, different colors and textures of PET sheets, the variety is very rich, and it is dazzling in the market. Of course, all products may have different characteristics.PET Sheet Production LineThere are often some small problems in the process. If we encounter such a problem, how do we need to solve it? Let's discuss this problem in detail.

The PET sheet production line may wrinkle during the production process for the following reasons: the distance between narrow and long workpieces is too small; there is no chamfer around the back plate; the horizontal and vertical distances of the workpieces are not in a straight line, and the resistance becomes larger; the temperature set by the machine Too high; the pressure set by the machine itself is too high. The reasons for the white color of PET sheets in the production process are as follows: the temperature set by the machine itself is too high; the pressure set by the machine itself is too high; the wiring is wrong.

A large part of the brittleness of PET sheets is caused by internal stress. There are many reasons for the embrittlement of the product, mainly due to equipment problems. There are dead corners or obstacles in the barrel, which are easy to promote the degradation of the melt. The plasticizing capacity of the machine is too small, and the plastic in the barrel is not plasticized enough; the plasticizing capacity of the machine is too large, and the plastic is heated and sheared in the barrel for too long, which makes the plastic easy to age and the product becomes brittle. The ejector is inclined or unbalanced, the top trunk section is small or the distribution is unreasonable.

If you findPET Sheet Production LinePlease don't worry, you can adjust the machine in time to avoid the above situation. If the PET sheet produced by the PET sheet manufacturer is pre-soaked in water, or exposed to the outside, or bent, stretched, etc., it will cause white fog and lose light transmittance. The following PET sheet manufacturers will analyze the phenomenon of PVC thickener soaking white fog, exposure to white fog and ground stress white fog.

Dip white fogging phenomenon: many transparent PET sheet products will appear turbid after prolonged exposure to water or steam. Soft products are stronger than hard products. In this case, even if the thickener is soaked in water, the thickener cannot be restored to the original state. Only by increasing the temperature can the solubility of the thickener be repaired and become completely transparent. White fog phenomenon: PET sheet products exposed to the outside, there will be white fog phenomenon. This is relatedPET Sheet Production LineThe solubility of the thickener used is dependent. In the metal soap polyvinyl chloride thickener, the atomization effect of benzoate soluble in polyvinyl chloride is not as good as polyether salt. In-situ stress white fog phenomenon: In-situ stress white fog phenomenon refers to the white fog generated by hard PET sheet products under the action of bending, stretching and other external mechanical equipment, and the bending, folding and stretching of PET sheet products.. phenomenon. This may be due to the change of molecular formula caused by external force, the molecular structure chain of the polymer causes the trend, the relative density of PVC changes, and there is a gap between some molecular structures, resulting in light transmittance, making the PET sheet Milky White.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

recommend News

Share