PET sheet production line production process description

Release time:

2022-10-17

PET sheet production line in the production, need to add raw materials. The main raw material is polyethylene terephthalate, which is a heat shrinkable polyester. The raw material of PET sheet is crystalline PET resin, and antistatic agent and color masterbatch can be added during the production process.

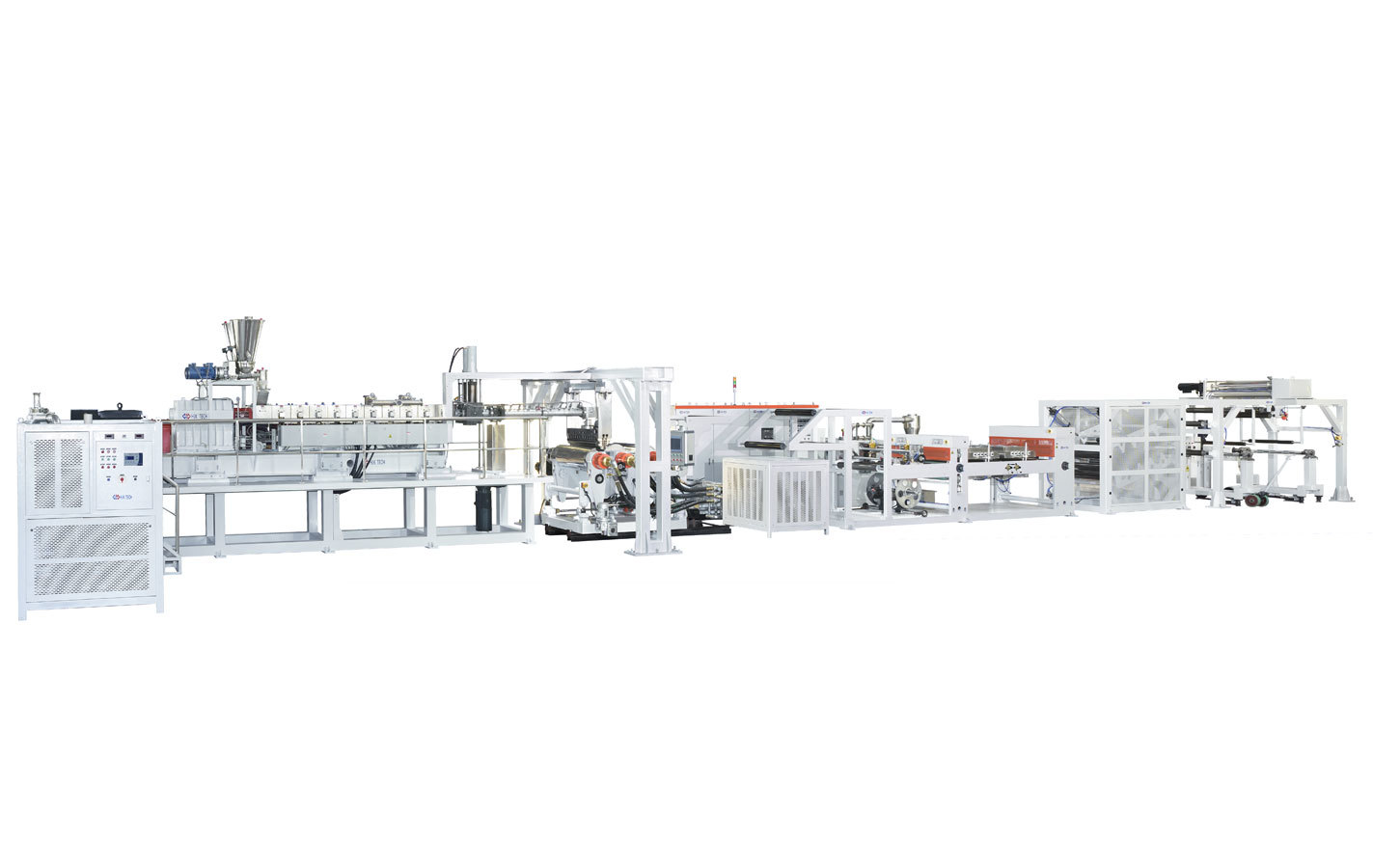

PET Sheet Production LineDescription of production process flow

PET Sheet Production Line

PET Sheet Production LineDuring production, raw materials need to be added first. The main raw material is polyethylene terephthalate, which is a heat shrinkable polyester. The raw material of PET sheet is crystalline PET resin, and antistatic agent and color masterbatch can be added during the production process. The PET sheet produced was an amorphous PET sheet.

Production process route and equipment: The production process of PET sheet is as follows: particle drying → extruder extrusion → net changing → calendering → support cooling → traction → winding → packaging. In the production process of PET sheet, the drying of raw materials is an extremely important process. In order to produce high-quality transparent sheets, it is necessary to provide a high-temperature air circulation of molecular sieve dehumidification and a suitable drying system with a "gas-to-material ratio" for continuous drying for more than 4 hours.

The production of PET raw materials will be carried out during the high-temperature extrusion melting process. If the raw materials contain moisture, it will cause great danger. The moisture content of undried pellets is usually 0.4%(mass fraction, the same below), and only through a proper drying process can the moisture content be reduced to less than 0.005%, in order to avoid the violent "hydrolysis" of the polyester polymer in the extrusion process, otherwise it will cause its "intrinsic viscosity" to decrease, sheet deterioration, product strength to decrease, uneven thickness, and even yellowing. and other defects. Particle drying is a physical process of heat and mass transfer. The removed water can be divided into two parts: the water absorbed by the surface of the particle and the water combined with the internal molecules. The former is easier to remove, while the latter penetrates into the particles and is more difficult to remove. Only when there is a water vapor partial pressure difference between the inside of the particle and the surface, the internal molecular bound water can diffuse to the surface of the particle and evaporate, and there must be enough time for the air to be heated by extreme dry heat.

PET Sheet Production LineTo discharge the PET raw material from the bottom of the main drying tower, the moisture content must be less than 0.005%, and then sent to the sealed hopper of the screw extruder for use. Screen changer and sheet head shall be equipped with screen changer according to the production process and production characteristics of PET sheet. Using the screen changer, impurities in the melt can be filtered out and high-quality PET sheets can be extruded. The sheet head is of coat hack type, and its main features are: the melt flow channel is narrowed by the width, and the melt flow channel is changed from cylindrical to slit. The key problem of the head design is to make the melt velocity uniform over the entire width of the runner and stabilize the extrusion pressure of the sheet, thereby improving the uniformity of the product thickness. Three-roll calender Three-roll calender is a device for calendering, cooling and shaping the surface of the sheet coming out of the head. It is the key equipment for the production of PET sheets. After a series of processes, we can see the materials.

Category complete cost-effective

With professional technology dedicated to product development, create cost-effective products to meet the different needs of customers.

Good quality trustworthy

Quality management is embedded in each production process during the production process. From raw material purchase to product manufacturing

Manufacturing, packaging, shipping, etc. have layers of inspection, supervision, and strive to create excellent quality.

Worry-free after-sales service

Careful service details highlight the quality of service!

recommend News

Share