What is the role of the casting machine?

The main function of the casting machine screen changer in the cast film extrusion process is to eliminate impurities in the melt and improve the physical and chemical properties of the cast film. So what is the role of the casting machine?

2022/08/26

What is the reason for the loud noise in the work of the PET sheet production line? Let's analyze it together. (1) motor parts. 1. The rotor shaft rolling bearing is severely worn or the bearing accuracy is low. 2. The rotor shaft is bent and deformed. 3. The installation position of the carbon brush is incorrect. 4. The rotor shaft end fan blade scraping motor is installed safely.

2022/08/16

The operation steps of PET sheet production line are introduced. Come and collect!

What are the operating steps of the PET sheet production line? Let's take a brief look at it. 1. PET sheet production line before the start of the inspection work. (1) Check the equipment use and maintenance records to confirm whether the equipment was used normally last time. (2) Determine the experimental materials and impurities that affect the normal operation of the equipment, and understand the basic properties (melting point, softening point, etc.) of the material is appropriate. (3) Check whether all parts of the equipment are in good condition, and whether the power supply and water supply meet the equipment operation requirements.

2022/08/08

Some knowledge of PET sheet, PET sheet production line manufacturers tell you

PET sheet production line manufacturers believe that PET sheet is a new type of material developed in recent years. It has excellent toughness, high strength, high transparency, and excellent environmental performance, can be recycled and reused, and will not produce harmful gases when burned. Because of the trend of environmental protection, PET sheets are gradually being valued by consumers and producers.

2022/07/27

Some common sense of PET, PET sheet production line manufacturers to explain for you

PET sheet production line manufacturers believe that the glass transition temperature of PET is about 165, and the crystallization temperature of the material is 120~220. PET is highly hygroscopic at high temperatures. For glass fiber reinforced PET, it is easy to bend at high temperatures. The addition of crystallization enhancers can increase the crystallinity of the material. Transparent products processed with PET have gloss and heat distortion temperature. Special additives such as mica can be added to PET to reduce bending deformation. If a lower mold temperature is used, a transparent product can be obtained by using unfilled PET material.

2022/07/18

2022 Photovoltaic Film Production Line Industry Chain

Photovoltaic film production line industry chain. From the demand for photovoltaic film, according to statistics, the global demand for photovoltaic film in 2020 is 16.1 billion square meters, of which the demand for EVA film is 11.5 billion square meters, the demand for POE film is 3.2 billion square meters, and the demand for co-extruded POE film is 1.7 billion square meters.

2022/07/07

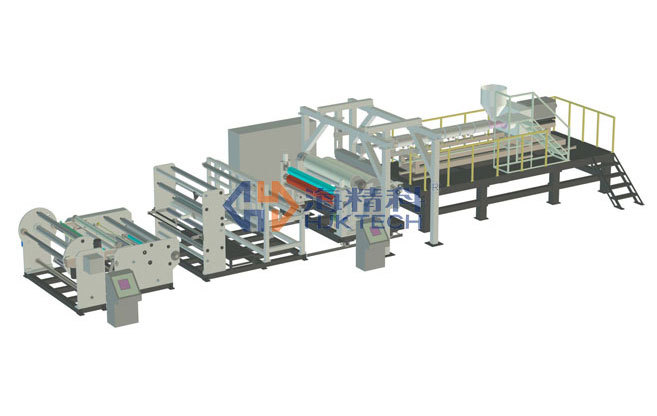

Solar Photovoltaic Film Production Line Industry Solution

At present, silicon solar cells are widely used in ground photovoltaic systems, which can be divided into monocrystalline silicon, polycrystalline silicon and amorphous silicon solar cells. Monocrystalline silicon and polycrystalline silicon cells are superior to amorphous silicon cells in terms of energy conversion efficiency and service life. The connection device between the solar cell array and the solar charging control device is a photovoltaic film production line composed of solar cell modules.

2022/07/01

Photovoltaic film production line: EVA solar packaging film and its production equipment

Photovoltaic film production line EVA film is a kind of thermosetting adhesive film, which can be used for glass intermediate clamping. Due to the superiority of EVA film in adhesion, durability and optical properties, it is more and more widely used in current components and various optical products.

2022/06/27

Photovoltaic Film Production Line-New Photovoltaic Film Material

The important material used in the production of photovoltaic modules in the photovoltaic film production line is photovoltaic film, which is used to produce photovoltaic modules to protect the batteries inside the modules. According to the different product structure, it is divided into EVA film, POE film and so on. The encapsulation film plays a role of wrapping and bonding in photovoltaic modules, and the POE film has better encapsulation performance and is widely used in double-sided modules.

2022/06/22

Photovoltaic Film Production Line-In-depth Analysis of Photovoltaic Film Industry

Nowadays, accelerating the development of renewable energy has become the mainstream direction of the global energy transition. The proportion of clean energy power generation has increased rapidly. Driven by cost competitive advantages, the proportion of photovoltaic power generation in the total power generation of global photovoltaic film production lines will increase from 2.4 in 2018 to 24% in 2050.

2022/06/16